J. Zhang et al., 2025

a) Layer of the cheese Tête de Moine with wrinkly edge, after being scraped using the cheese slicer “la Girolle.”(b) Edge wrinkling of a torn plastic sheet. (c) Wavy edge of a BlueStar Fern leaf.

J. Zhang et al., 2025

J. Zhang et al., 2025

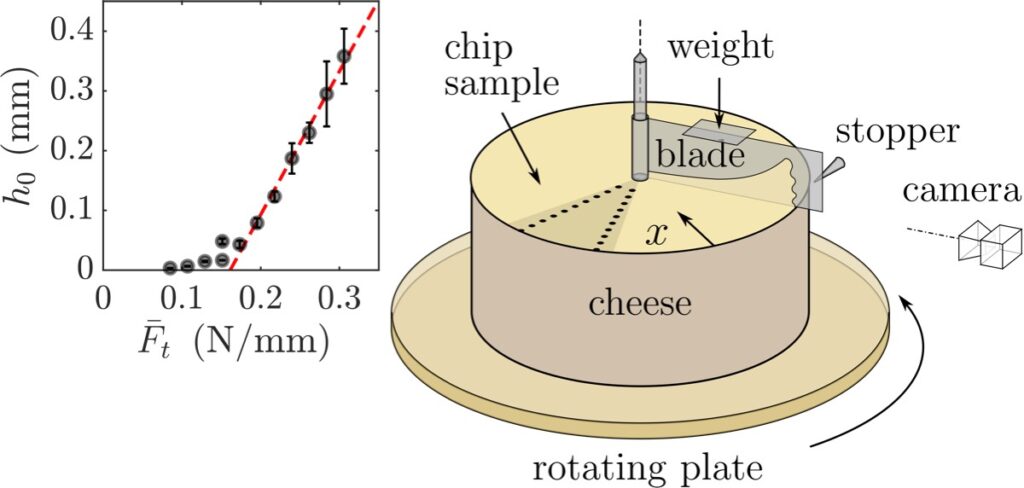

Schematic illustration of the experimental setup.

J. Zhang et al., 2025

a) Layer of the cheese Tête de Moine with wrinkly edge, after being scraped using the cheese slicer “la Girolle.”(b) Edge wrinkling of a torn plastic sheet. (c) Wavy edge of a BlueStar Fern leaf.

J. Zhang et al., 2025

Schematic illustration of the experimental setup.

J. Zhang et al., 2025

For their experiments, the authors of the PRL paper selected samples of Monk’s head cheese wheels from the Fromagerie de Bellelay brand that had been aged between three and six months. They cut each cheese wheel in half and mounted each half on a Girolle, motorizing the base to ensure a constant speed of rotation and making sure the blade was in a fixed position. Their measurements of how the cheese deformed during scraping enabled them to build a model based on metal dynamics on a two-dimensional surface that had “cheese-like properties.”

The results showed that there was a variable friction between the core and the edge of the cheese wheel, because the core stayed fresher during the ripening process. Because the harder outer edge had lower friction with the blade, the edges of the cheese shavings were uneven in thickness—hence the resemblance to frilly rosettes.

This essentially amounts to a new shaping mechanism with the possibility of being able to one day program complex shaping from “a simple scraping process,” per the authors. “Our analysis provides the tools for a better control of flower chip morphogenesis through plasticity in the shaping of other delicacies, but also in metal cutting,” they concluded. Granted, “flower-shaped chips have never been reported in metal cutting. But even in such uniform materials, the fact that friction properties control the metric change is particularly interesting for material shaping.”

Physical Review Letters, 2025. DOI: 10.1103/PhysRevLett.134.208201 (About DOIs).